Ihr innovativer Partner für Stanztechnik, Kunststoffhybridtechnik, Oberflächentechnik und Montagetechnik

Nesper ist einer der führenden Hersteller von Stanzteilen und komplexen Hybridkomponenten. Wir beherrschen alle relevanten Technologien bis ins Detail und sorgen mit einer konsequenten Null-Fehler-Strategie für präzise Lösungen in höchster Qualität.

Qualität macht den Unterschied

Unsere Qualität ist zertifiziert, aber vor allem von Anfang an spürbar. Um Ihre Aufgabe hochwertig und wirtschaftlich zu lösen, betrachten wir die gesamte Wertschöpfungskette. Dabei gelingen uns Ergebnisse mit außerordentlich engen Toleranzen in effizienten, IATF-zertifizierten Prozessen.

Spitzenleistungen für Ihre Branche

Spitzenqualität mit äußerst niedrigen Fehlerquoten zu wirtschaftlichen Konditionen. Damit meistern wir Ihre Anforderungen in anspruchsvollen Branchen wie Automotive, Medizintechnik, Elektronik. Für Zukunftsbranchen wie E-Mobilität oder Brennstoffzellentechnologie liefern wir ebenfalls innovative Lösungen.

Technologien

Bei Nesper setzen wir die ganze Bandbreite bewährter und neuer Technologien ein. Dazu gehören z. B. über 50 Stanzautomaten, der eigene Werkzeugbau, Planung kompletter Anlagen, Kunststoffhybridtechnik, das innovative Nesper Cleaning© und vieles mehr. Gewinnen Sie mit unserem Know-how jetzt Vorsprung.

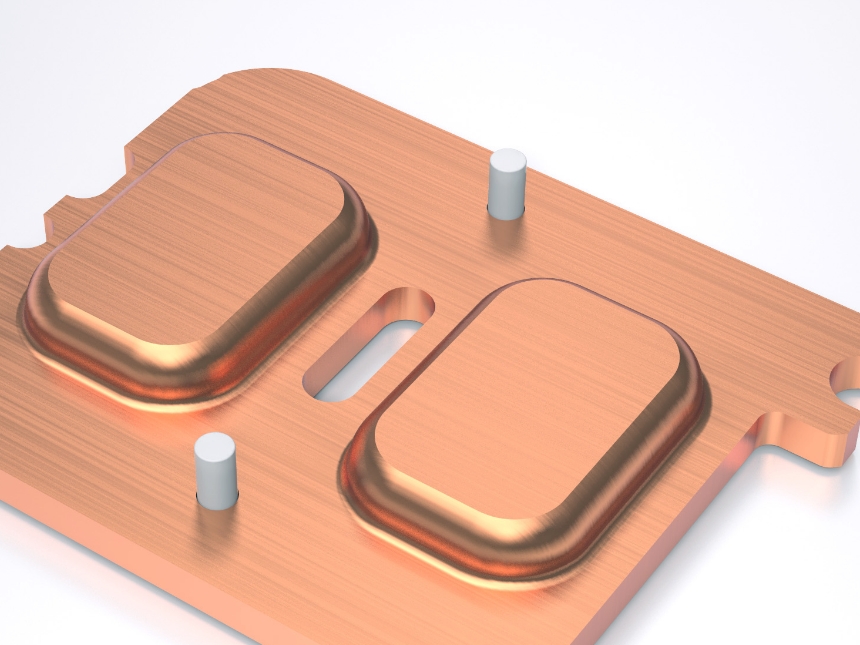

Werkzeugbau

Ideenreich und zielorientiert stellen wir hochleistungsfähige Stanz- und Umformwerkzeuge sowie Werkzeuge für unsere hauseigene Nietproduktion her. Auch komplette Produktionsanlagen für Automatisierungsanwendungen werden bei uns im Haus geplant. Dank durchgängiger Datenintegration können auf modernsten Bearbeitungszentren mittels Draht- oder Senkerosion sowie auf unseren Profilschleifanlagen komplexe Formen mit kurzen Durchlaufzeiten realisiert werden.

Stanztechnik

Wir schöpfen unsere Leistungsfähigkeit aus 50 Stanzautomaten mit einer Presskraft von 100–2.500 kN, Materialstärken von 0,04 mm bis 5 mm können verarbeitet werden. Wir verarbeiten in unserem Haus Buntmetalle, Stähle, Edelstahl und Aluminium. Eine Inline-100%-Prüfung sowie eine Inline-Reinigung, können wir im Bedarfsfall für Ihr Projekt vorsehen. Neben Schüttgut und Spulenware setzen wir seit Jahren verschiedene automatisierte Verpackungskonzepte ein, wie z. B. Trays, Blistergurte, Magazine oder Tubes.

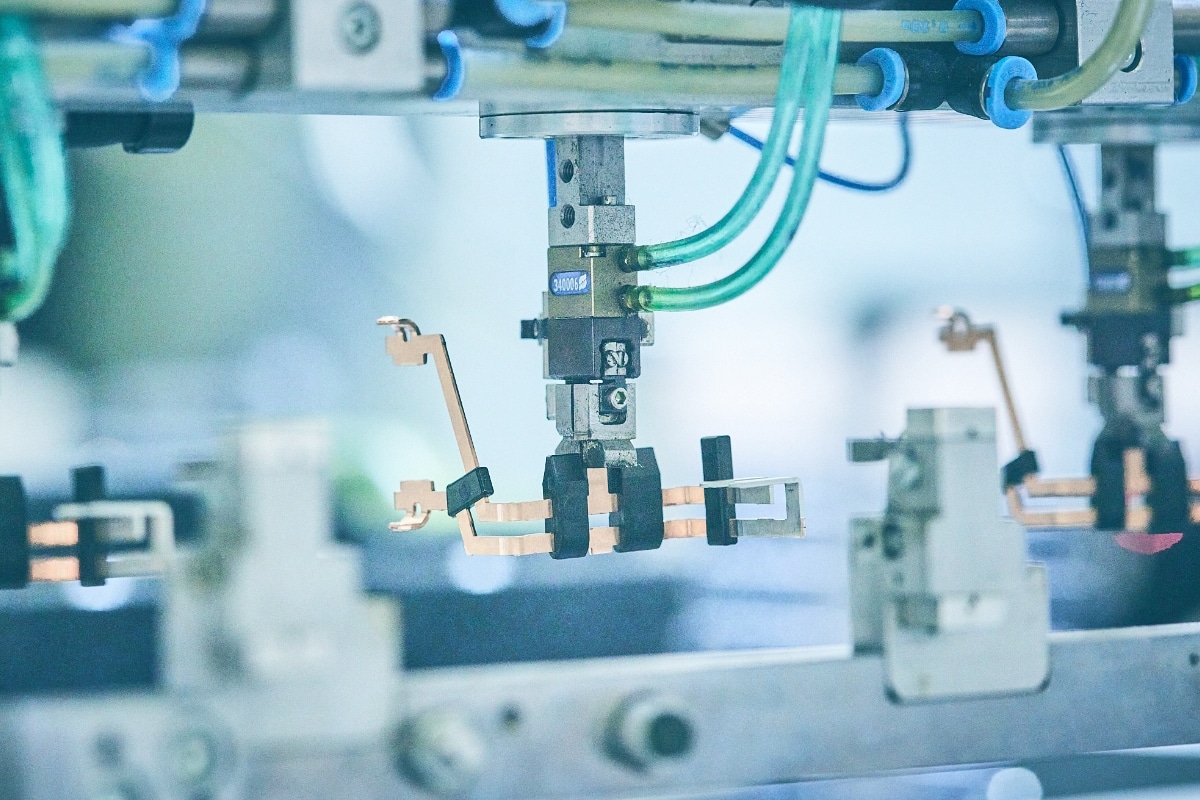

Montagetechnik und Automatisierung

Komplexe Zuführlösungen unter anderem für Nieten, Keramikstifte sowie gerissene Kontakte in Verbindung mit Schneid-, Biege- und Umformprozessen können implementiert werden. Eine vollautomatisierte Prüfung mittels 100%iger Kameraüberwachung und Inline-Reinigung sowie das anschließende Verpacken sind bei uns optional möglich. Auch Inline-Fügetechniken mittels Stanzpaketieren, Widerstands- oder Laserschweißungen, können prozessintegriert realisiert werden.

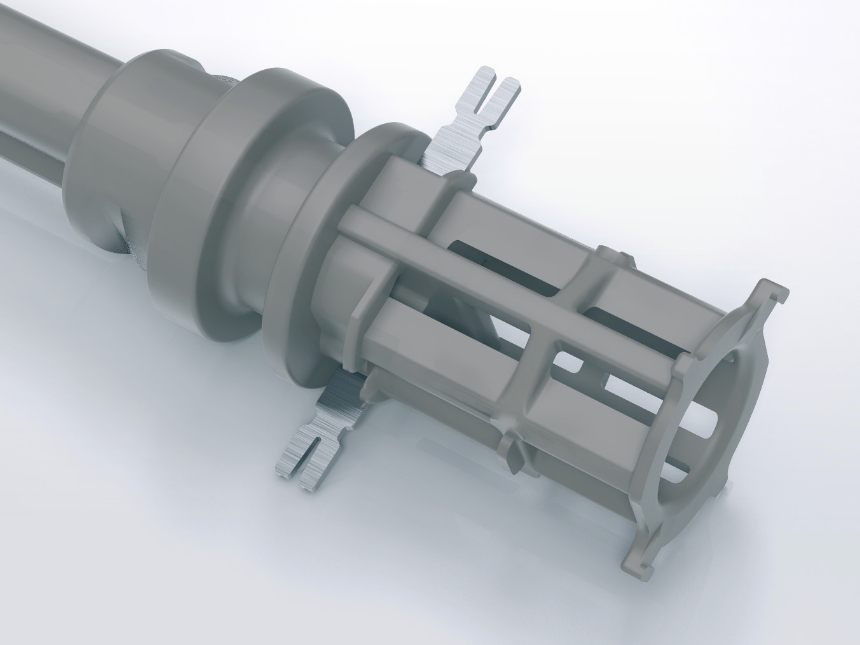

Kunststoff-Hybridtechnik

Ausgestattet mit Rundtischautomaten, Reel-to-Reel-Systemen sowie Werkstückträger-Umlaufsystemen, bieten wir Ihnen Produktionsmöglichkeiten für unterschiedliche Mengenanforderungen. Darüber hinaus erlaubt unsere Anlagenverkettung eine Fertigung mit vollautomatischer Verpackung in Trays, Magazinen, Blistergurten oder Tubes, inkl. 100%-3D-Vermessung im laufenden Prozess.

Oberflächentechnik und -veredelung

Unsere Systeme, die zum Teil Eigenentwicklungen sind, nutzen wir zur Teilereinigung auf wässriger Basis oder mit modifiziertem Alkohol für Schüttgut und Spulenware. Je nach Anforderung kommen nachgelagerte Einzelteil- oder Band-Reinigungsanlagen zum Einsatz, um Ihre Vorgaben für Restschmutz bis hin zu Bondqualität zu erfüllen. Unsere Partner für die galvanische Oberflächenveredelung sind Technologiespezialisten und Marktführer in Europa.

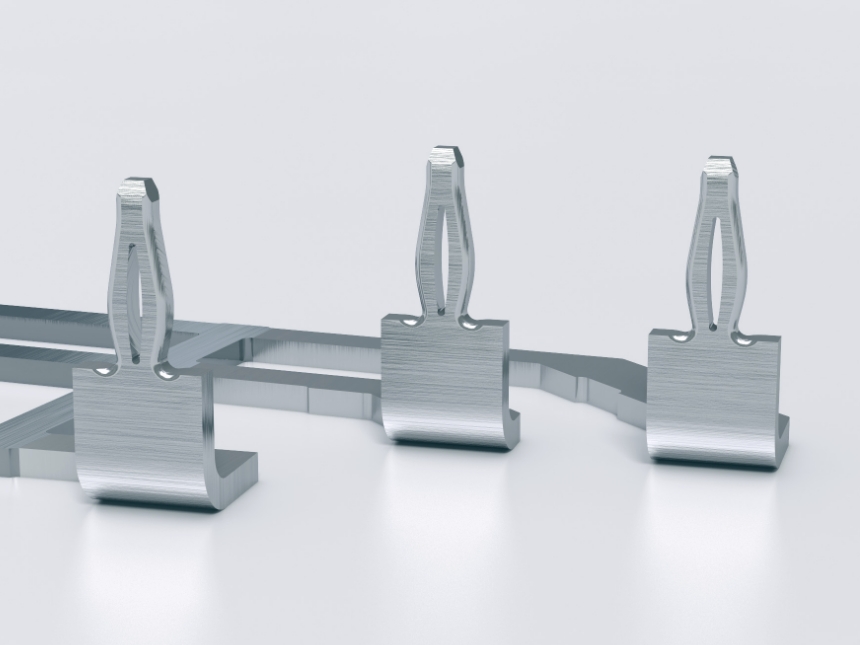

Niettechnologie

Einer unserer Schwerpunkte liegt in der Gestaltung, der Produktion und dem Einsatz von Kontaktniete. Einen weiteren Schwerpunkt bilden diverse Montagelösungen. Als erfahrener Hersteller mit selbstentwickelten Maschinen bieten wir Ihnen hochwertigste Qualität, wie sie in der Elektro- und Sicherheitstechnik, als auch in anderen anspruchsvollen Branchen gefordert ist.

Hauseigene Konstruktion

Als einer der führenden Hersteller von Stanzteilen verfügen wir über einen qualifizierten Werkzeugbau, der mit modernster Technologie ausgestattet ist und die Basis für individuelle und dennoch wirtschaftliche Lösungen bildet. Dabei meistern unsere Experten in der Konstruktion von einfachen bis hin zu hochkomplexen Folgeverbundwerkzeugen jede Herausforderung.

Wir brauchen Herausforderungen, Lösungen haben wir genug

Projekt- und Prozessentwicklung

Technologien

Kontakt zu NESPER

Einmalige Kundennähe, zwei Standorte

Standort Ispringen, BW, Deutschland

Niet-, Stanzteilefertigung und Kunststoffverarbeitung, Montage- und Reinigungstechnologie, Konstruktion und Werkzeugbau sowie Qualitätsmanagement sind hier zuhause. Die Produkt- und Prozessentwicklung sowie der Werkzeugbau werden von Ispringen aus zentral geführt.

Standort LaGrange, Georgia, USA

Auf 4.000 m2 Produktionsfläche erstrecken sich die Fertigungsbereiche Stanzen und zukünftig auch Kunststoff- und Hybridteilproduktion. Teilereinigung und ein Reparaturwerkzeugbau sind integriert.